- Topics

- Innovations

- Innovationen 2021

- On-site machining shortens maintenance processes in toolmaking

Sauber. Sicher. Digital

Warum die deutsche Autoindustrie die innovativste der Welt bleibt.

Warum die deutsche Autoindustrie die innovativste der Welt bleibt.

- Topics

- Innovations

- Innovationen 2021

- On-site machining shortens maintenance processes in toolmaking

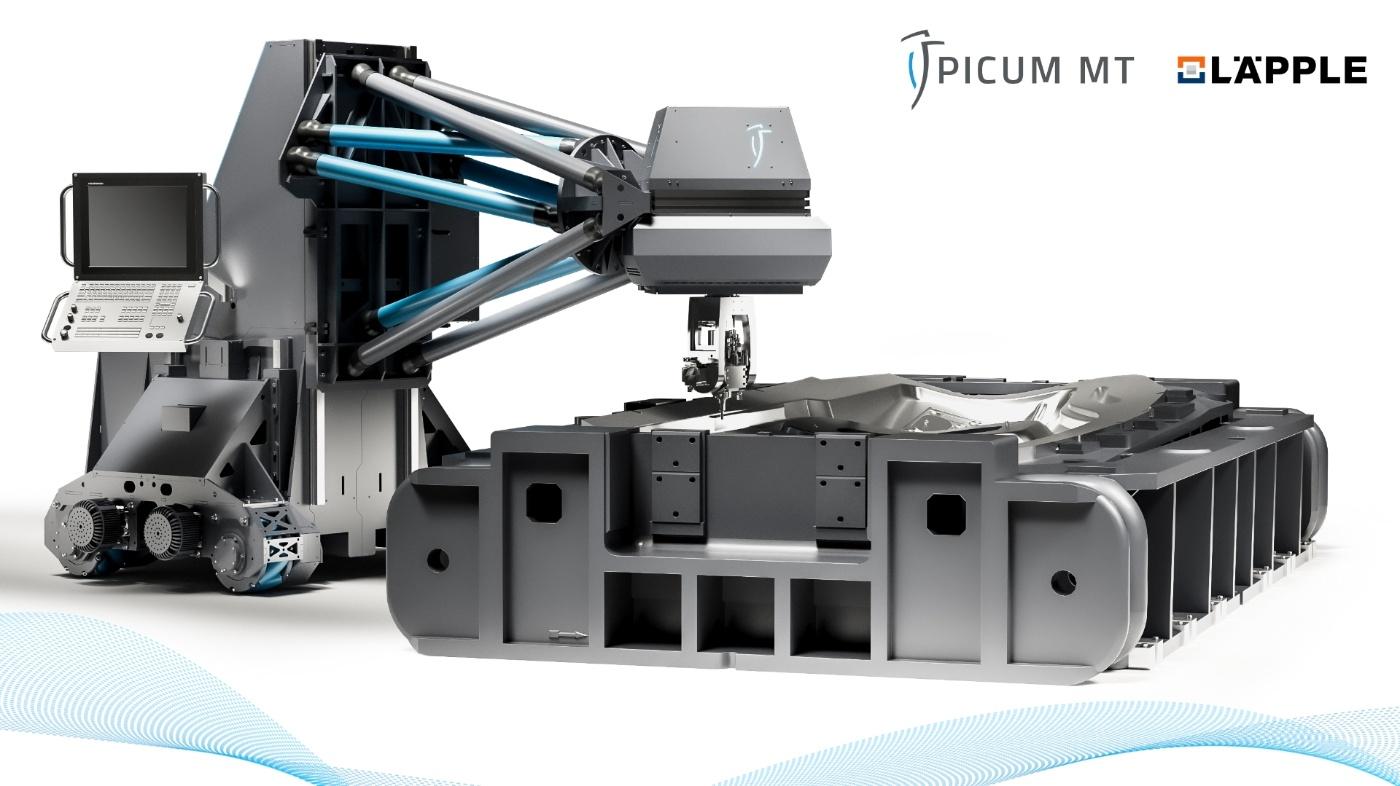

On-site machining shortens maintenance processes in toolmaking

Each automobile consists of around 350 sheet metal parts. The extremely heavy shaping tools used to press the sheet metal must be adapted, reworked, or repaired frequently during their life cycle. The Picum system shortens this complex process by around 40% of the throughput time, saving about 50% of the total costs of a factory adaptation for each use compared with the conventional modification process. This is made possible by complete on-site processing with a mobile system that holistically maps the process chain from digitization of the tool to the final finishing.

Sophisticated manufacturing processes are carried out directly on the component: Resulting in significant time and cost savings.

Invented by Dominik Brouwer and his team at Picum MT GmbH, responsible for the industrial application in automotive manufacturing, further developed with Läpple AG.

More details