- Topics

- Innovations

- Innovationen 2021

- Simulation software by Tenneco

Sauber. Sicher. Digital

Warum die deutsche Autoindustrie die innovativste der Welt bleibt.

Warum die deutsche Autoindustrie die innovativste der Welt bleibt.

- Topics

- Innovations

- Innovationen 2021

- Simulation software by Tenneco

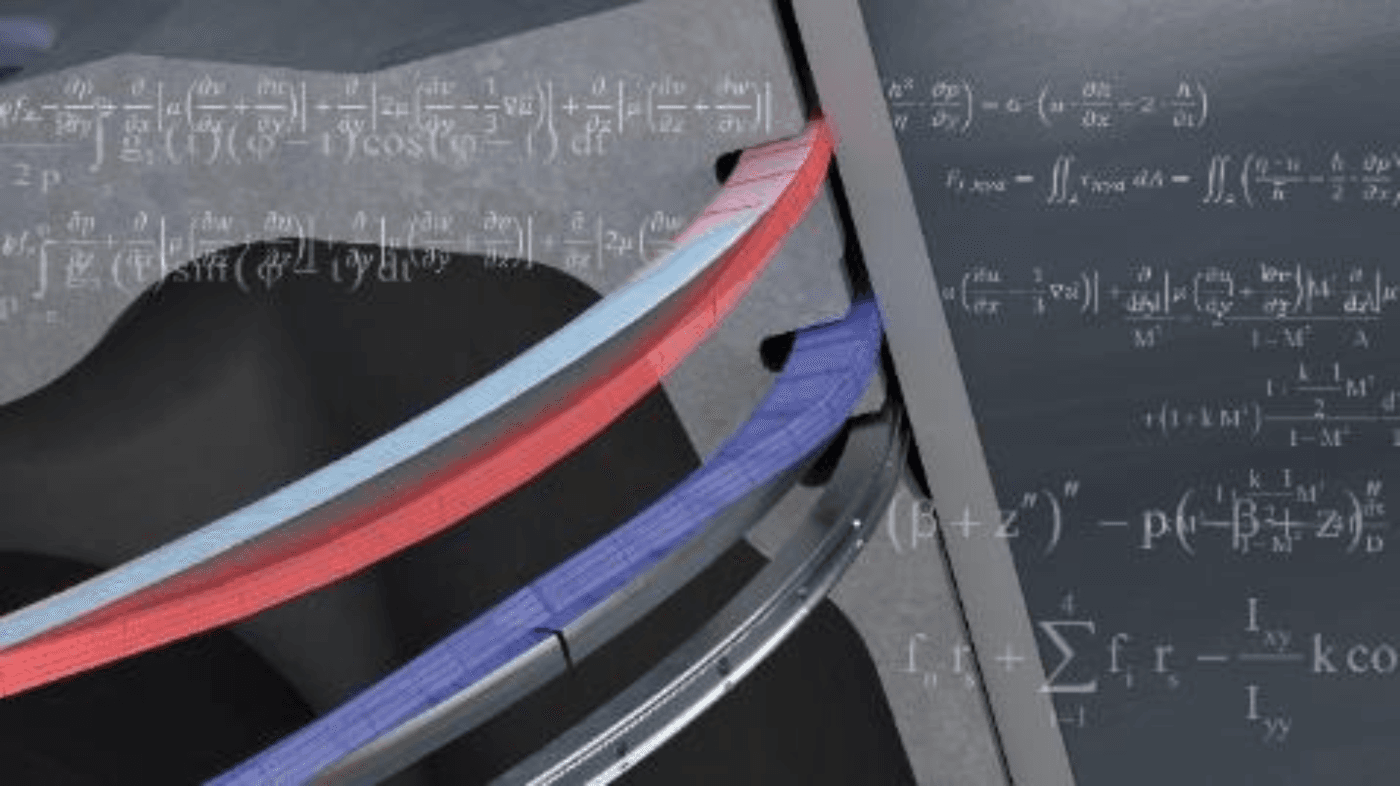

Simulation software shortens development time for cylinder components by up to 70%

Tenneco's award-winning PRiME3D® simulation software can reduce cylinder component development time by up to 70% by way of enabling – for the first time in the industry – a purely physical simulation model of the piston-ring system under real engine operating conditions during the development process. With the help of PRiME3D, piston and piston-ring designs can be optimized at an early stage, targeting minimized emissions and fuel consumption.

PRiME3D® combines extensive expertise from two decades of intensive research in the engine sector with the most advanced simulation tools, thus enabling the optimization of piston and piston-ring design with an accuracy level of almost 95%. Engine manufacturers have already used PRiME3D simulation software in more than 450 projects to help them achieve emission targets for relevant driving cycles, such as the WLTP (Worldwide Harmonized Light-Duty Vehicles Test Procedure). These projects have demonstrated blow-by reductions of up to 70%, friction optimizations of up to 20%, oil consumption reductions of up to 40%, and particulate emissions reductions of up to 70%.

With the aid of PRiME3D, piston and piston-ring designs can be optimized at an early stage, targeting minimized fuel consumption.

Invented by Tenneco developer team.

More details