Commercial vehicles

Battery, hydrogen, or e-fuels?

While it is possible to electrify commercial vehicles, it is more difficult. Which is why it is also worth looking at various climate-friendly drives.

- Topics

- Automotive industry

- Commercial vehicles

- Climate neutrality

Commercial vehicles play a key role in reaching climate goals

In September 2020, as part of the European Green Deal, the Commission proposed raising the target of reducing greenhouse gas emissions to at least 55% by 2030 compared to 1990 levels. In addition, total emissions in the transportation sector are to be reduced by 90% by 2050.

The Federal Climate Protection Act sets ambitious national climate protection goals for Germany, as well as compliance with European targets. Greenhouse gas emissions in Germany are to be gradually reduced compared with 1990 levels, such that by 2030 a general reduction quota of at least 65% will apply. To this end, annual reduction targets have been set for the energy, industry, transportation, building, agriculture, and waste management sectors. In addition, Germany has pledged to be climate-neutral by 2045.

Strategy for compliance with future CO2 limits

The commercial vehicle manufacturers and suppliers acknowledge their responsibility to make their contribution to achieving the climate targets with new drive concepts. As such, the following options are to be considered in the medium and long term:

- Battery-electric drive (all-electric or hybrid)

- Hydrogen in combination with a fuel cell or hydrogen combustion engine

- Use of synthetic and alternative fuels

Since technological developments are not completely predictable, none of the technology options should be disadvantaged or excluded prematurely. However, technological progress should also serve as an indicator to specifically promote certain options while avoiding any disadvantages compared to conventionally powered commercial vehicles.

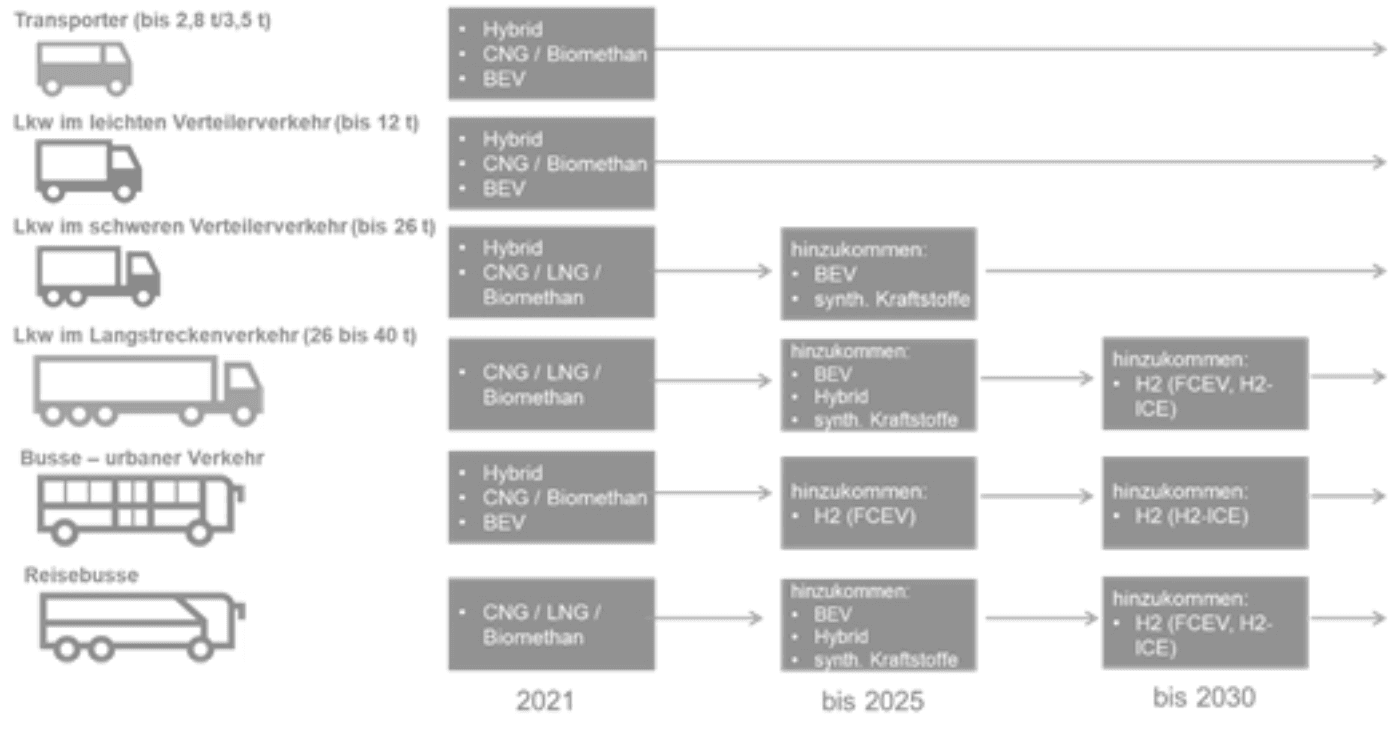

Since the purposes for which commercial vehicles are used vary considerably (light commercial vehicles up to 3.5 metric tons for inner-city or suburban distribution transport and commercial use among tradespeople, medium and heavy commercial vehicles in distribution transportation, the construction industry, the municipal sector, and long-distance transportation), different demands are also made of the vehicle's drive system. The following figure illustrates the planned use of various new drive technologies in future production vehicles in the individual segments.

Battery-electric drives

Electromobility offers the opportunity to make freight and passenger transportation emission-free. Light commercial vehicles are already available today with battery-electric drives and are increasingly being used for inner-city distribution. Medium-duty commercial vehicles for regional and distribution transportation in particular will take on transport tasks with battery-electric drives in the medium term. Further development of today's battery technologies will also enable applications in heavy-duty commercial vehicles (trucks/buses) for long-distance transportation. Corresponding field tests are in preparation. It is currently estimated that by 2025, approximately 10,000 medium-duty trucks (3.5 to 16 t) and 30,000 heavy-duty trucks (> 16 t) with battery-electric drive will be in operation in Europe (EU27 + UK). By 2030, the fleet in Europe will grow to approximately 70,000 medium-duty and 200,000 heavy-duty battery-electric trucks. This will require overcoming hurdles, particularly in long-distance transportation, arising from the vehicle's application and a charging infrastructure that is currently completely lacking. While the additional weight of the battery is moderate in view of the elimination of diesel components in many long-haul applications, and taking advantage of statutory rest periods for charging operations, the lack of a charging infrastructure is the main challenge to implementing electric drives in commercial vehicles for long-haul transportation.

Plug-in hybrid drives are one option important in paving the way for purely battery-electric drives. They are suitable for applications where conventional powertrains cannot yet be dispensed with. In many cases, hybrid drives fulfill a pilot function and advance the development of the charging infrastructure as well as progress with battery technology.

The ranges of all-electric heavy-duty vehicles, including buses in long-distance transportation, should reliably exceed 300 kilometers in the medium term, even in unfavorable weather conditions and challenging route topography. The performance of the electric drive will have to be based on today's performance data for internal combustion engines. To ensure this, batteries with at least 400 kWh of usable energy will be needed. Furthermore, the battery should be rechargeable within the driver's specified normal driving and resting times. Ideally, the battery should be able to be charged to around 80 percent within 45 minutes. However, this requires a continuous charging power of about 720 kW. An installed charging power of around 1 MW can compensate for charging losses and non-linearities. The existing CCS standard (Combined Charging System, 450 kW) is not sufficient for future commercial vehicles in long-distance traffic. This will require higher charging capacities in line with the Megawatt Charging Standard (MCS), which is currently being coordinated and theoretically has a capacity of up to 4.5 MW.

Tractor unit with semitrailer 40t/44t and tourist buses

| Range | 300 km |

| Battery energy capacity | 400 kWh |

| Charging time during min. rest period | 45 min |

| Continuous charging power | ca. 720 kW |

| Charging standard |

DC >500 kW (MCS) (in the initial phase also |

| Charging times while parked (overnight) | > 3 h |

| Charging power | > 100 kW |

| Charging standard | DC <350 kW (CCS) |

A comprehensive public charging network is needed along the most important transport axes for charging electrified buses and trucks in long-distance traffic. By 2030 there should be at least one megawatt charging station (DC > 500 kW) with at least four charging points every 100 kilometers by 2025 and every 50 kilometers on German highways and on major freeways. For buses, at least one charging point per location must be accessible. This must also take into account the urgently needed expansion of truck parking capacities. In Germany, a total of approximately 630 charging points (DC > 500 kW) are required at around 260 locations as a first step. By 2030, Germany would need to expand this to more than 8,000 charging points (DC > 500 kW) if battery-electric commercial vehicles comprise more than 20% of the fleet. This expansion must be tackled quickly so that the number of newly registered electrically powered heavy commercial vehicles is matched by a functioning charging infrastructure over the coming years. To this end, it is necessary to begin development immediately on the basis of currently available standards (for example, CCS with DC 350 kW). The transition to higher charging capacities of 720 kW to 1 MW should take place as soon as the MCS standard is available.

Between conurbations and freight distribution hubs: Medium-duty commercial vehicles

Medium-duty commercial vehicles have to prove themselves above all in local distribution and delivery traffic between conurbations and freight distribution centers. Since routes are shorter and payloads lower, the batteries can also be smaller. 300 kWh for journeys of at least 200 kilometers should be the benchmark. For charging (80%), there should be a charging capacity of at least 250 kW with a maximum charging time of one hour.

A broad public charging infrastructure network is also needed for charging distribution vehicles. However, this can be supplemented by charging facilities at depots, at the ramp of freight distribution centers or at rest areas. To this end, it is necessary to begin development immediately on the basis of currently available standards (such as CCS with 350 kW). A transition to higher charging capacities of 720 kW to 1 MW could be prepared as needed. Trucks in long-distance traffic would also benefit from the development of a charging infrastructure (DC < 350 kW) for overnight charging at the depot.

In any case, it is essential to promote the development of the charging infrastructure in close cooperation with the industry (freight carriers, fleet operators, bus companies) and to use green electricity as soon as possible.

Medium-duty commercial vehicles

| Range | 200 km |

| Battery energy capacity | up to 300 kWh |

| Charging time during min. rest period | 45 min |

| Minimum charging power | > 250 kW |

| Charging standard |

DC 350 kW(CCS) (with optional extension to MCS >500 kW) |

| Charging times while parked (overnight) | > 3 h |

| Minimum charging power | > 100 kW |

| Charging standard | DC < 350 kW (CCS) |

Conditions for implementing the strategies

In the next few years, vehicles with battery-electric drives will only have costs comparable to those of conventionally powered commercial vehicles if they are appropriately controlled (e.g., purchase subsidies, CO2 pricing, toll adjustments, etc.). This is due to the expensive technology but also to necessary investments in the charging infrastructure.

The development of a needs-based DC fast-charging infrastructure for heavy-duty commercial vehicles (trucks/buses) along German highways with continuous charging capacities of at least 720 kW per charging point must be tackled as quickly as possible. Priority should be given to the installation of charging points at German freeway service stations and truck stops. Possible conversions of rest stops/parking areas must be tackled in good time. Independently of this, charging points must be made available at companies’ freight distribution centers, logistics warehouses, depots, and freight distribution centers. This will require wide-ranging subsidy programs geared to the requirements of the commercial vehicle sector (trucks/tourist buses). Standards must be adapted and expanded for the high charging powers (>500 kW) and currents (1000 A), and international coordination is already ongoing. Providing the occupancy rates of public charging points can support route planning.

Involve operators at an early stage

Operators should be involved at an early stage in the definition of structural policy measures and possible subsidy programs. This applies both to the acquisition of the vehicles as well as to the establishment of charging facilities on the operational side. The entire funding policy should be designed for the long term while offering incentives for rapid fleet conversion.

Operators should receive partial relief from the electricity tax or relief from the EEG levy, similar to that of electric vehicles used in public transport.

Another way of promoting alternative drives in the commercial vehicle sector is a CO2-based truck toll. This can reduce the additional costs involved for vehicles with alternative drives.

Measures for technically improving current commercial vehicles and their trailers (e.g. aerodynamic measures, low rolling resistance tires or similar) are a supplement to improving the CO2 balance and should be treated as equally eligible for support. In addition, new technological approaches to CO2 reduction (e.g., e-axles on semitrailers) should be made eligible for registration as quickly as possible by adapting type approval legislation.

Contact person

Dr.-Ing. Sascha Pfeifer

Head of the Transport Policy Division